Inventory management for SMEs: Best practices and tools

Effective inventory management is a core profitability driver for SMEs, yet research consistently shows that poor stock visibility leads to cash being tied up in excess inventory or lost through stockouts. Studies from retail technology providers and SME-focused commerce platforms indicate that businesses using automated inventory systems achieve higher stock accuracy, faster turnover, and better demand planning compared to manual or spreadsheet-based approaches.

Best-practice inventory management for SMEs centers on real-time stock tracking, demand forecasting, and integration across sales channels. Tools such as Zoho Inventory, TradeGecko (now QuickBooks Commerce), and Cin7 help SMEs automate reordering, reduce human error, and align purchasing decisions with actual sales data. When inventory systems integrate directly with ecommerce platforms and POS systems, SMEs gain a single source of truth that improves fulfillment accuracy and customer satisfaction.

For most SMEs, the research points to a clear conclusion: simple, integrated tools outperform complex setups. By focusing on visibility, automation, and analytics rather than over-customization small and medium-sized businesses can control costs, improve cash flow, and scale inventory operations without increasing operational risk.

How Strong Inventory Management Builds Financial Resilience, Operational Accuracy, and Scalable Growth for SMEs

- Robust inventory management makes SME finances more resilient by maximizing cash flow, reducing carrying costs, and facilitating smart buying.

- Reliable on-shelf availability and trustworthy inventory information build customer confidence, loyalty and repeat business across multiple geographies.

- Whether you’re an entrepreneur or a large corporation, streamlined inventories and specialized management software are key for enhancing your operational flow, reducing mistakes, and staying flexible to change.

- Agile inventory strategies allow SMEs to react swiftly to market fluctuations and needs, while data-driven insights facilitate more accurate forecasting and minimize waste.

- Making the effort to train your team, implement clear handling procedures and instill a sense of responsibility lays the groundwork for accurate and reliable inventory.

- By embracing automation and analytics tools, you future-proof your inventory management, improve resiliency, and nurture sustainable growth at scale.

SME inventory management refers to how small and medium-sized enterprises (SMEs) manage their inventory and raw materials. Smart inventory management saves you money, keeps products on hand and prevents waste.

Most SMEs rely on software or simple tools to assist in balancing supply and demand. Selecting the appropriate system makes your day-to-day work easier, and it facilitates planning for growth.

In this post, find out what works best for SMEs and what to watch out for.

Why SME Inventory Management Matters

SME inventory management defines the core of business. It connects assets, revenue, and user satisfaction. When managed correctly, it does a lot more than just keep tabs on product it maintains cash flow, cultivates trust, and enhances responsiveness.

The proper system can save money, cut down on waste, and keep SMEs afloat during rough waters.

1. Financial Health

Effective inventory management enables SMEs to maintain tight control over costs. Inventory that lingers too long locks up capital, while being out of hot-sellers means missed opportunities. With strategies such as FIFO, companies can push older stock first and reduce spoilage.

This is key for keeping your balance sheet healthy and avoiding a financial hit from expired or obsolete products. If businesses are monitoring sales trends by inventory data, they can shop smarter and order only what’s necessary.

Less cash tied up in warehousing and less stale merchandise significantly drops storage costs, by up to 30% if you plan well or do things like drop shipping. Even the littlest miscount of stock can result in huge losses, so accurate data is important.

Lost or stolen inventory adds up as well. In 2015, worldwide companies wasted $1.75 trillion due to bad management. For SMBs, this can be the difference between staying open or closing your doors, particularly when times are rough.

2. Customer Trust

Dependable inventory systems ensure items are available when consumers desire them. This minimizes the risk of failing buyers with OOS notices or delayed shipments. When customers know they can rely on a business for fast, accurate orders, they’ll keep coming back.

Transparency about supply creates trust. It helps establish tangible expectations for when goods will ship. Inventory errors can wreak havoc, leading to mix ups, such as selling items that aren’t available, which damages trust.

Order consistency defines your customers’ experience and builds loyalty. This can transform every-time buyers into repeat buyers, powering consistent growth.

3. Operational Flow

Less inventory, of course, means less clutter. Leveraging software to monitor and update stock reduces human mistakes. Automated alerts keep staff aware of when to reorder or address low inventory, so issues get addressed before they escalate.

Defined processes for checking in, storing, and transporting inventory keep teams aligned. As we’ve seen, auditing these workflows can frequently help SMEs plug holes and increase efficiency.

4. Business Agility

Rapidly evolving markets demand rapid response. Adaptive inventory software assists SMEs in adapting stock quantities to emerging trends or unexpected demand fluctuations. Teams that experiment discover more effective ways to manage and distribute goods.

Access to real-time data allows employees to make snap decisions, so they can capture new opportunities or prevent losses from slow-moving inventory.

5. Data-Driven Growth

Inventory data, when tracked, can help identify trends and forecast. Forecasting tools rely on historical sales to predict what’s required in the coming season. This reduces waste and prevents over-ordering.

Turnover rates, for example, are a key metric because they reveal how effectively inventory is managed. These figures assist leaders in goal-setting and progress-inspection.

Common Inventory Pitfalls

Small businesses often encounter various inventory management challenges that can significantly affect cash flow, customer satisfaction, and operational efficiency. Without proper inventory management practices and efficient inventory management systems, issues like inaccurate data and poor demand forecasting can lead to stockouts and excess inventory, ultimately resulting in lost revenue and decreased productivity.

Common inventory management pitfalls in small and mid-sized enterprises (SMEs) include difficulties in receiving inventory and maintaining optimal stock levels, which can disrupt business operations. Implementing dedicated inventory management software can help streamline inventory management efforts and mitigate these challenges.

- Using manual spreadsheets to track, leading to error-prone

- Not finding and clearing dead stock, tying up working capital

- Conducting audits inconsistently, leading to inventory discrepancies

- Not having real-time inventory tracking leading to overselling or stockouts

- Not aligning orders with supplier capabilities, causing fulfillment delays

- Misjudging seasonal demand, making overstock and shortages more likely

- Administrative errors, accounting for 21.3% of inventory shrink for retailers

Spreadsheet Reliance

Spreadsheets are simple to get going, but once inventory expands, their boundaries become apparent. They’re not automated, don’t update in real time, and don’t manage advanced, multi-location operations effectively. Manual entry increases the risk of errors one overlooked cell or formula can cascade through your whole ledger.

This typically results in miss-matched stock levels and wasted reconciliation time. Moving to specialized inventory software reduces manual error, introduces automation, and maintains accurate records. These apps sync inventory levels, alert low or excess stock, and assist identify patterns.

Good staff training is the secret sauce people need to know how to use the software and why they should update it regularly. Establish strict data entry guidelines and perform periodic audits to identify errors quickly.

Ignoring Dead Stock

Dead stock stealthily consumes square footage and clogs capital. Stagnant goods pull down inventory turns and restrict introduction of new or quick selling items. If left unchecked, dead stock accumulates, clouding visibility into what actually moves.

Promotions, discounts, or bundle offers assist shift dead stock. Examine report frequently to identify sluggish items. Clear out through clearance or donation if necessary. An inventory turnover checkup emphasizes what doesn’t sell.

Monitor these and move fast to prevent additional losses. This forward thinking helps working capital free and storage costs low.

Inconsistent Audits

Without or infrequent audits, records slip out of alignment with reality. Clearly defined audit schedule keeps discrepancies from snowballing. Leverage technology, such as barcode scanners and apps, to accelerate cycle counts and spot checks.

Checklist for regular inventory audits:

- Schedule daily cycle counts of small stock categories

- Compare physical counts to recorded data for each batch

- Investigate and note down mismatches

- Correct errors in the system right away

- Document all audit results for compliance and analysis

When differences show up, move quickly. Correct the records and investigate the reasons, whether it be administrative mistake, theft, or supplier problem.

Poor Supplier Sync

Bad supplier links to underorder or stockouts. Develop deep relationships with strategic partners to guarantee shipments arrive on time. Automated reordering systems assist align inventory levels to supplier schedules, reducing the chance of running out or overstocking.

Keep in touch with vendors regarding order requirements and lead times, so everyone is aligned. Review supplier performance often late or incomplete shipments are a sign to seek new partners. That way, inventory remains well tempered, and customer needs are fulfilled without expensive lag.

Core Inventory Management Methods

Inventory is key to SME growth. Choosing the right method can reduce expenses, increase income, and liberate cash flow. The core methods manual, periodic and perpetual inventory offer varying levels of granularity and oversight.

Deciding on FIFO versus LIFO for cost accounting influences what the financial picture looks like and may affect taxes. More sophisticated systems, like JIT, prioritize eliminating waste and aligning inventory more precisely with demand. By applying EOQ to core inventory, SMEs order just enough, just in time, while safety stock methods help buffer demand variability.

The following table summarizes classic inventory management approaches and their characteristics.

|

Method |

Key Features |

|---|---|

|

Manual |

Simple, low-tech, high labor, prone to errors |

|

Periodic |

Regular counts, updates at intervals, less real-time insight |

|

Perpetual |

Real-time tracking, automated, needs reliable tech, higher upfront cost |

|

FIFO |

Oldest stock sold first, good for perishables, can show higher profits |

|

LIFO |

Newest stock sold first, may lower taxes in inflation, not always allowed |

|

JIT |

Order as needed, lowers holding costs, risk if supply chain breaks |

|

EOQ |

Calculates best order size, balances ordering and holding costs |

|

Safety Stock |

Extra stock as a buffer, prevents running out, needs careful planning |

Stock Flow

A robust stock flow process maintains inventory at the proper level, and catches mistakes early. First, implement a systematic approach to control the flow of merchandise.

- Scan inventory as it comes and goes with barcodes or RFID.

- Log every motion in a central database for quick retrieval.

- Set thresholds for minimum and maximum stock levels.

- Schedule regular checks to compare records with physical stock.

- Use reorder points to generate orders before you run out.

Track stock flow daily. It assists in identifying slow movers and overstock, prior to it affecting cash flow. Review your sales and inventory trends to understand what moves quickly. Leverage these trends to schedule new buys that won’t lock up cash in stale goods.

Demand Pacing

Demand pacing means inventory aligns to what customers want to buy, when they want it. Project demand based on historical sales, market analysis reports and input from sales personnel. Modify your warehouse quantity whenever you observe obvious seasonality or marketplace changes.

Use sales data to revise forecasts and adjust orders, so inventory aligns with present demand rather than outdated trends. Collaborate with your sales force to find out what customers request the most. Their feedback lets you anticipate new trends before the numbers do!

Small teams can meet weekly to swap insights and identify changes early.

Value Prioritization

Concentrate on the most profitable items. Begin by categorizing your inventory by its selling power and margin granting ability. Use the ABC analysis: ‘A’ items are top earners and should get most attention, ‘B’ are mid-level, and ‘C’ are low movers.

Put tighter controls on ‘A’ items real-time tracking and frequent reviews. Cheaper goods, check more simply, but don’t overstock money. Check product profit and turnover rates frequently.

Drop or discount low performers, and increase orders for best sellers. Value-based decisions keep capital working where it counts.

Selecting the Right Tools

SMBs face real challenges when selecting inventory management software. Choosing a solution that meets your immediate needs and scales with you can significantly impact both your day-to-day operations and future success. The ideal inventory management system should strike a balance between convenience, integration with other systems, and affordability. Here are key considerations to help guide your choice.

Assess Needs

Begin by simply enumerating what the business really needs to do inventory well. Some require barcode scanning to quicken checks, others desire live stock updates or easy order tracking. If you’re a company processing hundreds or thousands of transactions a month, the system needs to be able to keep up with that without lagging.

Enlisting your team in the process counts, too, since they understand the everyday problems that can make or break a new tool’s effectiveness. Establish objectives for the new system. Do you want to eliminate manual work or errors or simplify reordering stock?

Find any holes in the process now perhaps order management is sluggish, or tracking has too many mistakes. Create a wishlist of features such as automated notifications, in-depth analytics, or smartphone access. Consider privacy as well. Inventory systems contain sensitive business information, so robust data security is mandatory.

Price is also a piece of the needs analysis. Not every pricing model is right for every business. Certain tools bill on a per user basis, some by transaction or a flat rate for a subscription. Pair the budget with the features you really need, so you’re not paying for unused extras.

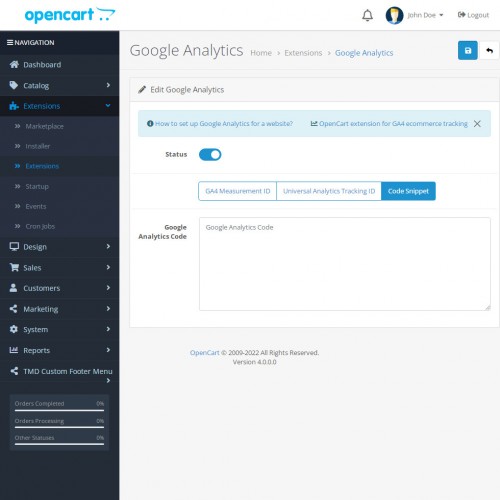

Check Integrations

Inventory software must play nice with what you’ve already got. Most SMEs use accounting tools, ERP or ecommerce platforms or CRMs. If the inventory tool doesn’t integrate nicely, employees might find themselves entering duplicate information in multiple locations, which wastes time and invites mistakes.

Try integration options prior to selecting. Some providers even provide free trials or demos use them to test out connecting up actual workflows! Search for API access if custom connections are required. This can future proof your setup, allowing you to incorporate new tools or migrate platforms as the business evolves.

As much as possible, seamless connections keep things flowing and minimize the chance of interruptions.

Plan for Growth

Select something that scales with the business. If you’re going to expand into new product lines or multiple locations, ensure that the software can accommodate multi-site management and can scale to a larger volume of transactions. Some tools restrict SKUs or users so cross-check such caps with your plans.

Choose tools that are sophisticated, even if you don’t require all the features immediately. This prevents an expensive change down the road. Think about the simplicity of adding users or new features.

Gauging the potential ROI by saving time, eliminating mistakes and enhancing order accuracy is more difficult. Schedule the implementation thoughtfully so the new process nests in daily rhythms without significant upheaval.

The Human Element in Inventory

Humans power all aspects of inventory in SMEs, molding the way businesses maintain lean stock, reduce errors, and anticipate market shifts. Sure, software and tools assist, but human skills and decision-making still dominate. They have to deal with numerous complexities, from inventory monitoring to decision-making regarding what to order and when.

There is a perpetual push and pull between accuracy, speed and cost. Training, strong protocols, and a culture of trust are every bit as important as any tool. Even small lapses manual data entry errors, missed communications, or poor handoffs can result in massive costs, overstocking, or lost sales. Confronting these realities begins with human beings, not just processes.

Team Training

Good inventory management begins with all members of your team being trained. Employees should know more than just how to count and track what you have. They need to learn how to make optimal use of inventory tools.

Training can be more than just orientation. They should cover identifying demand trends, managing kitting/bundling decisions and reacting to sudden market shifts. This is to demonstrate to your teams how to utilize digital systems to minimize mistakes, detect stockouts and optimize order timing. Continuous training is important because inventory software changes and new features release. Workshops, peer learning, and updates from the industry keep the entire team sharp.

Your team members should feel comfortable to ask questions or flag issues. To cultivate a supportive climate, leaders have to emphasize that error is a teaching moment. Open forums or regular check-ins will surface challenges and novel solutions. This can help make teams more disruption-ready and more flexible when demand surges or subsides.

Clear Protocols

They establish a baseline via well-written protocols for how inventory is received, stored, and tracked, which is crucial for efficient inventory management. These protocols serve as a source of consistency, minimize confusion, and accelerate the ramp-up time of new staff. It’s important that protocols encompass each touch point scanning items, modifying counts, processing returns, and even making adjustments using the right inventory management system.

These measures significantly reduce mistakes due to manual entry or missed inspections. A periodic review of these protocols is essential as business needs and inventory management software evolve. Squads must be aware that flows will be revised to accommodate new risks, like supply chain delays or demand forecasting shifts, which can impact inventory control techniques.

It’s essential to convey these procedures via training, easy to reference guides, and ongoing updates. When all proceed the same way, inventory records remain accurate, and expensive errors like stockouts or overstocking are less probable. Clear communication assists teams in responding to disruptions quickly, ensuring proper inventory management practices are upheld.

Fostering Accountability

Putting clear roles in place is a sensible approach to injecting accountability and precision into inventory. When everyone on the team understands their role, it reduces gaps and redundancies. Performance metrics like error rates or fulfillment speed allow managers to monitor how well the humans are helping the inventory.

Acknowledging those that do well promotes pride and additional incentive to do precise work. An ownership culture implies employees will care about doing things right, not just the rapid completion of tasks. Regular feedback, one-on-one and as a team, provides room to revisit errors and celebrate successes.

This continuous cycle of feedback and appreciation fosters personal development as well as team success.

Future-Proofing Your Stock

Inventory management for SMEs means more than tracking stock. It’s about building a system that can handle change, meet customer demand, and adapt to new trends. That kind of future-proofing using technology, data, and smart planning means your business can react fast when markets shift.

Periodically, going through what’s in stock and purging the slow sellers typically the ones that haven’t moved in 6-12 months keeps your inventory lean and nimble.

Embrace Automation

Automated tools capture tasks that used to require hours, significantly enhancing inventory management efficiency. Automated tracking systems reduce errors and accelerate stock updates, while barcode scanning and RFID tags enable employees to audit inventory with a rapid scan instead of manual labor. Implementing effective small business inventory management practices is crucial for maintaining optimal stock levels.

Automated reorder points ensure stock is ordered before it runs out, based on sales rates and lead time to restock. This is particularly important as research reveals that 63% of shoppers who encounter an out-of-stock item will shop elsewhere or abandon the purchase. For small businesses, adopting the right inventory management system can mitigate such risks.

Robotics and AI bring an additional dimension to inventory control. Robots can sort, pack, and move goods in warehouses, liberating team members to focus on more cerebral efforts. AI can forecast demand spikes, identify shortages, and recommend restocking strategies, which enhances overall inventory management capabilities.

Periodic monitoring of these systems ensures they remain a good fit as the business expands or pivots, enabling efficient inventory management and smoother operations. This proactive approach is essential for optimizing supply chain management and maintaining customer satisfaction.

|

Technology |

Benefits |

|---|---|

|

Barcode/RFID |

Faster, error-free tracking |

|

Automated Reorders |

Maintains stock, reduces manual work |

|

Warehouse Robots |

Higher productivity, fewer errors |

|

AI Forecasting |

Better demand planning, avoids stockouts |

|

Cloud Inventory |

Real-time data, anywhere access |

Leverage Analytics

Inventory analytics is key for future-proofing your stock. With dashboards and custom reports, managers can see what flies off the shelves and what gathers dust. Following turnover rates and sales trends allows you to anticipate orders, match customer demand, and implement the FIFO (first in, first out) principle to maintain freshness.

Analytics data indicates when to establish new reorder points, depending on the speed of sale and supplier shipping times. Perpetual inventory records, paired with routine physical inventories, detect errors and maintain accuracy.

Examples of analytics tools for inventory management:

- Microsoft Power BI: Custom dashboards for stock flow and sales.

- Tableau: Visualizes turnover rates and demand shifts.

- Google Data Studio: Combines sales and inventory for better planning.

- Zoho Inventory: Tracks real-time stats and automates reorder alerts.

Build Resilience

Contingency plans help businesses stay prepared for supply chain hiccups, such as delayed shipments or unexpected surges in demand. By establishing ties to multiple suppliers, companies are not left stranded when one source hits a snag.

When you review your inventory rules like reorder points and safety stock policies remain in step with market changes. Fast-adapting teams are better at managing surprise.

Training and open discussions on new technology or process changes help cultivate an adaptive workplace culture. Syncing stock with actual sales, and staying ahead of automation trends, make sure the right stuff is always available.

Conclusion

To manage smart inventory in a small or mid-size store, maintain eagle eyes on what flows and what stalls. Leverage easy tools scaled to your size and your speed. Train your staff to identify slow movers and bare shelves quickly. Use numbers to identify patterns, not just to complete paperwork. A solid strategy slashes lost items and saves money. Seek opportunities to combine traditional expertise with innovative technology. Experiment with cloud tools or phone apps that mesh with your daily grind. Every step makes your shop bigger and leaner. Want to go deeper or exchange tips? Take a peek at the blog or ask a question. Here’s to making small shops savvy and spry in a hurried haven.

Frequently Asked Questions

What is SME inventory management?

SME inventory management is the way small and medium-sized enterprises utilize efficient inventory management techniques to keep tabs on, order, store, and regulate inventory. This prevents companies from overstocking, cuts expenses, and ensures enough inventory is on-hand when necessary.

Why is inventory management important for SMEs?

Good inventory management practices help prevent stockouts and overstock, leading to optimized cash flow, reduced warehousing expenses, and increased customer loyalty critical attributes for small businesses aiming for scalability and competitiveness.

What are common inventory management mistakes for SMEs?

Common errors in small business inventory management include poor stock records, lack of inventory tracking systems, excessive ordering, and neglecting demand trends, which can lead to lost revenue and squandered efforts.

Which inventory management methods work best for SMEs?

Common inventory management methods like FIFO, JIT, and ABC are essential for small businesses; the optimal approach varies based on the scale of sales and product nature.

How can SMEs choose the right inventory management tools?

Find something simple that works for your small business inventory management needs and provides features such as real-time tracking and reporting. Cloud solutions can be more flexible and scalable for an expanding SME.

What role do employees play in inventory management?

Women safeguard, confirm, capture, monitor, oversee, manage, correct, and double-check inventory, underscoring the importance of training your staff on proper inventory management techniques.

How can SMEs future-proof their inventory management?

Embrace technology and utilize efficient inventory management practices, while following the market and auditing your procedures regularly.