Small Business Inventory Management: How to optimize stock control with an integrated point of sale system

Small businesses consistently struggle with overstocking, stockouts, and poor inventory visibility, all of which directly impact cash flow and customer satisfaction. Research from retail and commerce technology providers shows that businesses using an integrated point of sale (POS) system where in-store and online sales data sync automatically achieve significantly better stock accuracy and faster replenishment cycles compared to those relying on manual or disconnected systems.

Why integrated POS systems improve stock control

An integrated POS connects sales, inventory, and reporting in real time. Every transaction updates stock levels instantly, reducing human error and eliminating delays between sales and inventory records. Platforms such as Shopify POS, Square POS, and Lightspeed are widely adopted by small retailers because they centralize product data, pricing, and stock counts across physical and digital channels.

Data-driven demand forecasting and reordering

Integrated POS systems collect historical sales data that helps small businesses identify fast-moving items, seasonal trends, and slow stock. This enables smarter reordering decisions based on actual demand rather than estimates. Studies from retail technology providers show that data-led replenishment reduces excess inventory carrying costs while improving product availability—two critical factors for small businesses operating with limited working capital.

Multi-location and omnichannel visibility

For businesses selling both online and offline or across multiple locations an integrated POS provides a single source of truth for inventory. Stock can be allocated dynamically between stores, warehouses, and ecommerce channels, preventing double-selling and improving fulfillment accuracy. This capability is especially important as more small businesses adopt click-and-collect, local delivery, and hybrid retail models.

Reduced shrinkage and operational errors

Automated stock adjustments tied directly to POS transactions reduce discrepancies caused by manual updates, theft, or administrative mistakes. Integrated systems also support role-based access, audit trails, and barcode scanning, which collectively strengthen internal controls and improve inventory accountability.

Practical optimization takeaways for small businesses

Research-backed best practices for optimizing stock control with an integrated POS include:

-

Centralizing inventory across all sales channels

-

Using real-time stock alerts and low-inventory thresholds

-

Reviewing POS analytics weekly to identify demand patterns

-

Syncing suppliers and reorder points to sales velocity

-

Avoiding standalone inventory tools that don’t integrate with checkout systems

For small businesses, inventory accuracy is no longer just an operational issue it’s a growth lever. An integrated POS system transforms inventory management from reactive stock tracking into a predictable, data-driven process that supports scalability, profitability, and a better customer experience.

How Smart Inventory Management Helps Small Businesses Reduce Risk, Boost Efficiency, and Support Long-Term Growth

- With the right software, small business can avoid wasted capital, lost sales and reputational damage that can threaten long term growth and financial health.

- Automate and optimize your inventory processes with automation tools, analytics, and point-of-sale, e-commerce, and accounting integrations to minimize manual errors and maximize efficiency.

- Define your metrics, predict demand, and establish control points to prevent overstocking and stockouts so your products never run out.

- Focus on inventory management systems that are scalable, provide real-time tracking, integrate easily and have great support so they can grow with you.

- Cultivate a competent team and robust vendor relationships to fortify your supply chain, yet don’t overlook the importance of engaging with your customers to ensure your inventory strategies meet market demands.

- Be forward-thinking by adopting technology, keeping an eye on industry trends, and devising contingency plans for shifting market dynamics and supply chain issues.

Inventory management for small businesses is tracking products, understanding demand, and replenishing them strategically. Good inventory habits keep those little shops from running out or overstocking.

Most use spreadsheets or inexpensive software. These clear records reduce waste and save money. Stock mistakes damage sales and cash flow.

Later, check out straightforward advice and actual examples to aid select the ideal plan for your store.

The true cost of poor inventory management

Bad inventory management sucks a business dry in more ways than one. Financial, reputational and operational costs all rack up quick. Inventory isn’t a mere budgetary line— it’s living flesh in any company, molding cash flow, client confidence, and expansion possibilities. Small businesses, in particular, feel the pressure as every resource matters.

Here’s an analysis of the real costs and risks that shoddy inventory oversight delivers.

Wasted capital

Overstocked goods hold capital that could be utilized in other ways. When items collect dust, that money is stuck in the warehouse, not ready to be spent on emergencies or invested or used as fuel for expansion. These inventory carrying costs can be 25% to 40% of average stock value annually.

Storage fees, insurance, taxes and even write-offs from expired or obsolete goods all add up quickly. This wasted capital makes it difficult for a business to pivot or react in a rapidly-changing market.

- Rotate stock regularly to reduce holding old items

- Use demand forecasting to plan and order smarter

- Set reorder points to avoid overbuying

- Clear out slow-moving goods with timed promotions

Because with too much inventory, you are paying for additional storage space, increased insurance and occasionally increased taxes. For others, the tax bill increases simply because additional inventory lingers in the warehouse come year-end. Thoughtful inventory management reduces these expenses and liberates capital for what counts.

Lost sales

Stockouts drive away customers and damage business reputation. When buyers don’t see what they want, they go somewhere else. Quite a few won’t come back. Monitoring how frequently and what items run out and auditing sales data indicates where the holes are.

Missed sales from empty shelves cost more than revenue lost they erode loyalty over time and make it difficult to reclaim business. Data trends identify what products are frequently out and when, allowing owners to prepare for peak periods.

A proactive system reordering before inventories are depleted helps satisfy demand. In high season, contingency plans like added vendors or short-term stock spikes avoid stockouts and lost revenue.

Damaged reputation

Customers notice when products aren’t available. More than 80% of negative reviews in retail and ecommerce cite delivery or stock problems. Negative feedback travels quickly and damages future sales.

Monitoring reviews and feedback from customers allows you to catch issues early on. Companies that respond quick to criticism and address the problems maintain their faith. A great brand comes from being dependable.

Shelves and orders build loyalty and, when customers know they can count on you, they come back.

Inefficient operations

Manual inventory checks are a huge time waster and leave you wide open for errors. If you’re using a barcode system or software to streamline your processes, you will be faster and more accurate. Automation translates to less opportunity for mistakes, improved traceability and more time for employees to spend on other tasks.

Regular flow checks identify bottlenecks and assist in tuning tasks. Staff training brings it full circle when your team is informed on the most efficient practices to monitor and handle inventory, your operation becomes more efficient and expenses decline.

|

Cost Type |

Revenue Impact |

Customer Loyalty |

Operational Costs |

|---|---|---|---|

|

Excess Inventory |

Negative |

Neutral/Negative |

High |

|

Stockouts |

Negative |

Negative |

Medium |

|

Poor Oversight |

Negative |

Negative |

High |

|

Smart Management |

Positive |

Positive |

Low |

How to master inventory management

To master inventory management you need to know what you have, what sells and how fast. This is crucial for small businesses that want to control costs and provide good service. Well-managed inventory is what prevents overstocking, under-stocking and shrinkage.

There are four main types of inventory: raw materials, finished goods, work-in-progress, and MRO (maintenance, repair, and operating supplies). Each requires separate tracking and planning.

1. Establish a baseline

Begin by gathering detailed information on existing stock levels for your entire range. From raw materials to work-in-progress, finished goods and MRO items. Next, examine historical sales trends. This highlights what goes fast and what sits.

Write down your stock process, from accepting stock to selling or consuming it. This outlines vulnerabilities, such as paperwork mistakes or points where shrinkage can occur. Define clear goals. For instance, reduce stockouts by 10% or increase turnover for slow movers.

2. Forecast demand

Leverage analytics to identify sales patterns. Review sales data from previous months or years, and observe trends. Account for seasonal changes such as holiday surges or trends that may shift the demand.

Poll your salespeople to get a feel for what customers are requesting. Then, adjust your orders according to what you anticipate selling. This can prevent under and over stocking of popular items.

3. Set control points

Establish reorder rules. For each, select a minimum quantity your reorder point that generates a new order. Include safety stock to absorb demand spikes. Monitor the turnover for each, so as to best correspond sales with restocking.

Low stock alerts mean you’ll never sell out and lose a sale. For perishable goods consider the FIFO method to keep inventory fresh and minimize spoilage.

4. Automate tracking

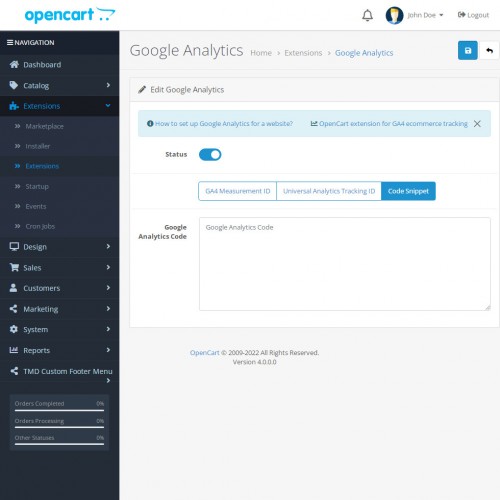

Invest in inventory management software to keep tabs on stock in real time. A barcode or RFID system assists in updating counts efficiently and reduces errors. Integrate your tracking system with your POS so sales and inventory update simultaneously.

Automation liberates your staff and prevents manual mistakes. It assists in identifying and managing shrinkage, which may be from theft, fraud, or errors.

5. Analyze performance

Take inventory reports frequently to monitor how effective your procedure is. Identify things that aren’t moving and consider marketing or discounting. Get granular use data analytics to see where you can improve efficiency.

Tweak your strategy as you learn from the numbers. Regular counting annual checks and spot counts helps catch errors early and halt losses. These steps cut expenses, increase revenues, and ensure customer satisfaction.

Choosing your inventory toolkit

Choosing your inventory toolkit is about aligning features to your small business’s real needs. No extended search necessary. Today’s best are super easy to use and play nicely with other tools, too.

Top software provides an easy dashboard, keeps setup time short, sometimes just a few days, and ensures you don’t lose sales, even during peak times. For the majority, a good toolkit is one that integrates with existing workflows and scales as the business scales.

These are the essentials to look for:

- Real-time tracking and reporting

- User-friendly dashboard and quick setup

- Cloud-based access for remote teams

- Direct integrations with key platforms (like QuickBooks, Shopify)

- Import options for Excel/CSV files

- Support for multiple locations (if needed)

- Analytics for sales and inventory trends

- Reliable vendor support and onboarding guides

Core features

Good inventory management hinges on a system that can track stock in the moment, produce precise reports, and provide actionable analytics. For small businesses, these elements are a must they prevent overstocking or running out of essential items.

Multi-location support is crucial if you have multiple points of sale, warehouses or channels. An intuitive, easy-to-use UI means employees pick it up quickly critical, because training shouldn’t bottleneck your operation.

It is critical to have real-time access. It assists leaders in making intelligent, rapid decisions, particularly when demand surges or declines. Great software allows you to see what’s in stock, what’s selling, and what needs to be reordered, all from one location.

Yearly counts and continuous spot-checks come easy when the system does all the tracking for you.

Scalability

A wise selection expands with your enterprise. Seek inventory management solutions that scale — able to accommodate more products, users, or locations as your needs evolve.

Some systems allow you to add functionality or upgrade plans without switching platforms, which makes expansion seamless. Cloud-based options, in particular, are flexible, allowing you to access your inventory remotely from anywhere with an internet connection.

Planning for tomorrow is about more than selecting a tool for today. It’s about choosing a toolkit that won’t strangle you if you open new stores or add online sales.

Integration

Compatibility is the key. Your toolkit of choice should play nicely with your POS, accounting and e-commerce systems. That is, direct, bi-directional integrations with things like QuickBooks or Shopify.

Smooth data sharing saves time and reduces errors. API access is another bonus. It allows you to construct tailored connections between your platforms, so your company operates as one, integrated entity.

The majority of software now features Excel or CSV import tools to make setup and future migrations simpler.

Support

Responsive support is essential. Inventory fires don’t wait, so the software provider has to provide quick, effective assistance when you require it.

Check for training guides and clear documentation along with live chat or phone support. User communities and forums are great, too. They provide user tips, best practices and when official support is tied up.

Integrating systems for seamless control

Small businesses encounter genuine challenges in integrating sales, inventory, and finance systems. Manual steps bog things down and introduce potential for error. Retailers integrating these fundamental tools experience less mistakes, improved efficiency and real-time visibility of inventory and sales across channels.

Cloud-based software simplifies this, allowing teams to monitor inventory and sales anytime, anywhere, on any device. Making these systems play nice with one another requires some planning, testing, and patience especially when operating with limited resources or older technology.

When done correctly, integration leads to less time lost and better decision-making, enabling companies to be agile and thrive in rapid markets.

The point of sale link

Linking your POS to inventory tools is a low-hanging fruit. It tracks stock levels in real time eliminating manual audits and helping avoid both stockouts and surplus. When someone makes a purchase, it removes it from your inventory immediately.

POS sales data is good for more than just tracking inventory. It allows owners to identify what sells quickly and what sits too long. This information aids in more intelligent purchasing decisions, so retailers don’t lose money on things that don’t move.

Real-time stock updates, activated by every purchase, keep inventory counts precise. This enhances what consumers encounter at checkout they aren’t going to purchase items that are out of stock. It expedites reordering, as low-stock items can set off alerts or even auto-orders.

A POS integration makes for transparency into what’s available, what’s moving, what needs to be reordered. It eliminates mistakes, makes you more efficient, and assists you in delighting customers.

E-commerce connection

Integrating e-commerce with inventory is crucial for online sellers. When sales platforms and inventory tools communicate, stock levels remain coordinated across channels. That prevents overbooking and delights guests.

Smart systems allow companies to monitor inventory figures across the board, from e-commerce to brick and mortar outlets. This simplifies restock and promotion planning, even during frenetic sales seasons.

Sales trends from e-commerce channels reflect what’s hot to help owners plan ahead for demand and stock-outs. With all orders flowing into a single system, order fulfillment accelerates, too.

Reduced errors, quicker turnaround, and less manual follow-up happier customers.

Accounting synergy

Linking inventory to accounting software links your finances and your stock. This connection keeps accounting reports current, as every inventory adjustment updates the ledgers.

Inventory value automates reduce accounting time. It additionally reduces the chances of mistakes that might impact tax returns or profit monitoring.

|

Metric |

Description |

Financial Impact |

|---|---|---|

|

Inventory Turnover |

Rate stock is sold and replaced |

Affects cash flow, profitability |

|

Stock Valuation |

Value of current inventory |

Impacts balance sheet accuracy |

|

Cost of Goods Sold |

Direct costs tied to sales |

Influences profit measurement |

|

Shrinkage |

Lost or stolen inventory |

Impacts gross margin |

Connected systems assist with following expenses associated with inventory such as warehousing charges or shipping fees, providing a complete picture of product movement and expenditures.

The human side of stock control

Inventory control isn’t just about stock; it involves people who operate the systems and make decisions, crafting the experience for customers. For small businesses, effective inventory management and the human side of inventory management processes are equally important.

Team training

It all begins with training to build a skilled team capable of efficient inventory management. Employees must understand how to utilize stock control software and the importance of each step. Educating them on best practices such as how to organize storage spaces, label items, and monitor inventory levels minimizes errors and maintains the inflow inventory.

Cross-training is also important; when employees know how to perform multiple tasks, the operation can continue seamlessly if someone is absent or shifts switch. This flexibility is crucial for small enterprises.

Training should not be a one-time event. As processes and technology evolve, so must the training. Periodic workshops or short update sessions keep everyone current. With new inventory management tools introduced, staff need hands-on experience, not just a manual to peruse.

They need to know how to identify slow moving items, as this is essential to recognizing what doesn’t sell. They might have to go on sale if you don’t want them tying up capital.

Frequent manual inventory counts are still key, even with a POS. These checks catch mistakes and confirm accuracy. Trusting just annual counts is dangerous by the time you discover issues, it’s too late.

Vendor partnerships

Suppliers are not merely points-of-goods they’re the human side of stock control. Good vendor relationships guarantee a trusted supply chain, which is necessary to have stock levels spot on. Demand swings may result in stockouts, lost sales and unhappy customers, or overstocking, cash flow straining and costly.

Contact with vendors should be continuous. Share your predictions and sales trends to keep vendors aware. Work on terms, like payment terms, minimum orders or lead times, to suit your business.

Work together to control lead times and prepare for seasonal transitions or promotional events. Great relationships can eliminate the danger of stockouts or overstocking.

Checklist to foster strong vendor partnerships:

- Share sales data and demand forecasts.

- Agree on clear reorder points and quantities.

- Review contract terms regularly.

- Hold feedback sessions to address issues.

- Work together on lead time planning.

Customer feedback

Customer insights are a fantastic inventory compass. 55% of shoppers don’t purchase a substitute when there is an out-of-stock. Out-of-stocks can lose a store every 100 customers.

Requesting feedback via brief surveys, face-to-face conversations, or online reviews demonstrates to customers that their input is valued. This feedback analysis aids to determine what to restock and what to drop or promote.

If shoppers complain again and again about out of stock items, priorities shift. By responding fast to these concerns, it can translate one-time shoppers into loyal buyers, particularly when paired with engagement and rewards within the community.

A customer-centric approach is about more than serving needs it’s about pre-empting them. By listening and responding to feedback, the businesses remain relevant and keep their shelves stocked with what people desire.

Future-proofing your inventory strategy

Future-proofing your inventory management system means designing a system that continues to function as markets, technology, and supply chains evolve. For small businesses, it’s not merely about keeping up it’s about future-proofing your inventory strategy for both growth and downturns. A solid inventory strategy minimizes losses due to shrinkage, theft, and spoilage, while ensuring products reach customers when they’re due.

Keeping up to date with evolution in your industry is crucial. Trends in buying, new regulations, and shifts in demand can alter your stock requirements. When you monitor sales and trends, you gain insights into what flies off the shelves and what doesn’t. This assists you in determining what to invest in and what to divest from, enhancing your inventory management capabilities.

For instance, a boutique electronics retailer may experience an uptick in demand for a new device and react swiftly, whereas a grocery store can leverage sales data to prevent overstocking of perishable items using effective inventory control techniques.

Small businesses can start with simple spreadsheets, but once things ramp up, transitioning to inventory software assists in tracking orders, shipments, and inventory levels. Barcoding is a simple yet powerful step: it speeds up stock checks, lowers mistakes, and lets you spot missing or damaged items fast.

Others deploy FIFO, where the older goods sell first critical for food, medicine, or anything with a shelf life, because it reduces waste and keeps stock fresh. Flexible strategies count. Markets evolve quickly, your system should not be hard-coded.

Define stock control policies minimum and maximum levels, reorder points, backorder rules so you have enough on hand but don’t keep too much money tied up in surplus. Having a stock controller a person or team who handles orders, deliveries and checks keeps things moving smooth and minimizes mistakes.

Preparedness for supply chain issues is key. Disruptions could be from natural disasters, shipping delays or sudden demand spikes. Annual stock counts, as well as spot checks, catch inventory issues before they become a big deal.

An emergency plan lets you move quickly if a shipment is delayed or a supplier is out. Whether that’s backup suppliers or an established protocol to reorder fast, so you don’t disappoint customers.

Conclusion

Small shops run smoother with clear stock plans. Everything from easy tracking apps to connected sales and stock systems help entrepreneurs maintain the perfect inventory. Staff perform better when they understand the process and can identify missing or delayed items quickly. There are all kinds of improvements and even small changes, like maintaining daily lists or shelf labels, make a powerful impact. Smart stock control saves money, reduces waste, and keeps customers happy. Shops that experiment with new tools or trade tips with peers can remain nimble, even as the landscape shifts. For more tips or to share your own hacks, join the conversation in the comments or subscribe for updates. Let’s keep shop life savvy and simple.

Frequently Asked Questions

What is inventory management for small businesses?

Efficient inventory management is crucial for small businesses, as it involves tracking, ordering, and storing goods to prevent stockouts and optimize cash flow.

Why is poor inventory management costly?

Bad inventory management can lead to lost sales, excess inventory, and increased storage costs, ultimately damaging your reputation and cash flow while stunting your small business growth.

How can small businesses master inventory management?

Small businesses should utilize efficient inventory management methods, monitor inventory levels, and leverage digital tools to ensure effective inventory control.

What tools help with inventory management?

Inventory management software and mobile inventory apps help automate tracking, minimize mistakes, and save time for small businesses through efficient inventory management.

Why should inventory systems be integrated?

Integrating systems links sales, accounting, and small business inventory management data. This provides real-time insights, simplifies operations, and enhances decision-making.

How does staff training impact inventory control?

Trained staff enhance efficient inventory management by minimizing human errors and increasing accuracy. Their expertise leads to smarter stock management and reduced shrinkage.

How can small businesses future-proof their inventory strategy?

Embrace scalable software solutions for small business inventory management, pay attention to industry trends, and keep inventory management processes fresh to ready your business for scaling and evolving customer demand.